AUTOSAR UDS Diagnostic Stack Implementation for Automotive Tier-1 ECU

How ElectRay Integrated AUTOSAR UDS Diagnostics into a Non-AUTOSAR ECU Platform

Technologies

- Infineon TC23x MCU platform

- TASKING VX-Toolset for embedded software development

- RTOS based ECU software environment

- AUTOSAR Classic R4.4 UDS Stack

- ISO 14229-1, ISO 15765-2 compliance

- Vector CANoe for simulation and validation

- CAPL scripts for ECU diagnostics & reprogramming workflows

Business Need

The Tier-1 supplier required a production-ready, UDS diagnostic stack that could be integrated into a safety-critical ECU built on the Infineon TC23x platform. The client needed to leverage their existing, optimized, non-AUTOSAR RTOS platform for cost efficiency and performance, which precluded the use of a AUTOSAR OS and BSW stack. The OEM required comprehensive diagnostic capabilities, seamless integration with the ECU’s existing software architecture, and robust flashing/reprogramming support for manufacturing, aftersales, and service workflows.

ElectRay was engaged to deliver a fully compliant UDS stack, validate it using OEM-specific test environments, and support integration activities through SOP.

Description

ElectRay had already developed a fully AUTOSAR-compliant UDS software stack, supporting all core diagnostic services defined by ISO 14229-1, along with a comprehensive Diagnostic Event Manager (DEM) featuring full Fault Memory functionality including DTC handling, freeze frames, extended data, aging, and healing. This production-grade, modular stack is deployed globally across multiple passenger-vehicle and motorcycle OEM programs.

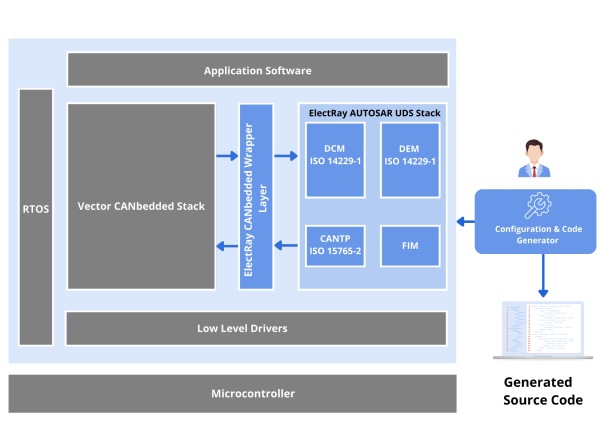

For this engagement, the target ECU software framework was non-AUTOSAR, with the Vector CANbedded CAN communication stack being one of the integrated components. To ensure seamless interoperability, ElectRay engineered the CANbedded Integration Wrapper Layer, a custom middleware enabling reliable communication between ElectRay’s AUTOSAR aligned UDS modules and CANbedded APIs. This wrapper layer effectively translated the AUTOSAR defined interfaces into the specific CANbedded API calls for message transmission and reception, thereby maintaining the integrity of the AUTOSAR diagnostic state machine logic within the non-AUTOSAR environment.

This approach allowed AUTOSAR-style diagnostics to operate effectively within a non-AUTOSAR environment, one of the key technical achievements of the project.

Challenge

- Cross-Architecture Integration: Bridging an AUTOSAR UDS stack with a non-AUTOSAR ECU using the Vector CANbedded stack for CAN communication required designing the ElectRay CANbedded Integration Wrapper Layer.

- OEM-Specific Diagnostic Requirements: Mapping OEM defined session logic, security levels, DIDs and diagnostic lifecycles.

- Diagnostic Event Manager (DEM) Complexity: Delivering full DTC status handling, freeze frames, extended data records, aging, healing, and fault-memory behaviour.

- Timing & Robustness: Meeting strict P2/P2* timing requirements, managing NRC responses, and ensuring resilience to malformed diagnostic requests.

- Multi-Vendor Software Ecosystem: Coordinating across several software vendors to ensure smooth functional integration.

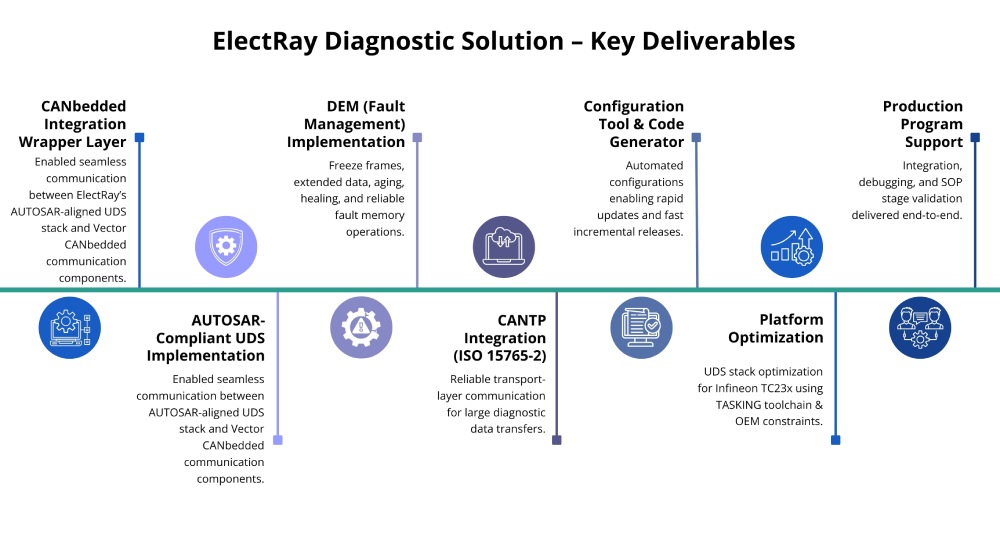

- ElectRay CANbedded Integration Wrapper Layer: Enabled seamless communication between the AUTOSAR-aligned UDS stack and the Vector CANbedded communication components.

- AUTOSAR compliant UDS Implementation: Delivered complete diagnostic service coverage, including session control, security access, communication control, memory operations, and routine management.

- DEM Implementation: Included freeze frames, extended data, aging, healing, and robust fault-memory operations.

- CANTP Integration: Implemented ISO 15765-2 transport layer for reliable large-data transfers.

- Configuration Tool & Code Generator: Configuration updates and accelerated incremental release cycles.

- Platform Optimization: Tuned UDS stack performance for Infineon TC23x using the TASKING toolchain and OEM-specific constraints.

- Production Program Support: Delivered integration, debugging and SOP stage validation.