Industry Overview

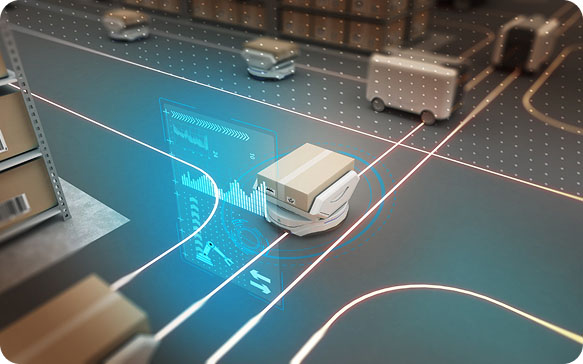

Autonomous Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are transforming intralogistics, manufacturing, and warehouse operations. As factories move toward Industry 4.0 and warehouse automation accelerates, OEMs are shifting from basic guidance systems to intelligent, connected, and autonomous mobility platforms.

ElectRay delivers production-grade AGV and AMR software solutions and independent engineering services, covering navigation and autonomy algorithms, embedded control software, safety systems, fleet orchestration, and cloud integration. Our engineering-led approach helps manufacturers build reliable, precise, and scalable industrial robots that perform consistently in dynamic, high-throughput environments.

Industry Challenges We Solve

AGV and AMR manufacturers face increasing technical and operational demands, including:

- Higher navigation accuracy in congested indoor environments

- Adaptive autonomy for obstacle-rich layouts

- Interoperability with warehouse systems (WMS, ERP, MES)

- Safety compliance (ISO 3691-4)

- VDA 5050 and communication protocols

- Optimized energy usage for longer duty cycles

- Remote diagnostics and predictive maintenance

- Fleet-level coordination and task management

Traditional line-following or QR-code systems are increasingly being replaced by LiDAR-based SLAM, vision-guided navigation, multi-sensor fusion, and AI-enabled autonomy. ElectRay supports OEMs across this full transition helping them reduce development cycles, accelerate deployment, and improve robot reliability.

ElectRay’s Core Capabilities

Applications We Serve

- Warehousing & intralogistics

- Manufacturing plants

- E-commerce fulfillment centers

- Distribution hubs

- Automotive & electronics assembly

- Hospitals & commercial facilities

- Material transport & towing robots

- Intelligent pallet movers & lift AMRs

Why ElectRay for AGV/AMR Engineering?

- Industrial-Grade Robotics Expertise

Deep experience across SLAM, sensor fusion, robotics middleware, motor control, embedded software, and edge-cloud integration. - Engineering-Led, Architecture-Neutral Approach

We adapt to your robot architecture, ROS-based or custom without forcing automotive frameworks or rigid platforms. - Faster Development & Deployment

Reusable libraries, pre-validated navigation components, and configurable architectures reduce time-to-market. - Safety-Aligned Engineering

Development aligned with ISO 3691-4, functional safety principles, and industrial automation standards. - Fleet-Ready Scalability

Designed for multi-robot coordination, high throughput, and large warehouse deployments.