The Future of Vehicle Diagnostics in the SDV Era: Moving from Distributed ECUs to Zonal Intelligence

10-Minute Read

In late 2024, North American logistics operators using Uptake’s predictive fleet platform with Daimler Trucks, including Freightliner and Western Star, experienced a significant change in how they managed issues. Instead of waiting for dashboard warnings or physical breakdowns, fleets started receiving targeted alerts through Uptake Fleet: “Predictive alert: Sign of component-level degradation; actionable service recommended. Failure forecasted well before any fault code.”

A manager for a large multi-regional fleet described a situation where Uptake’s models detected abnormal sensor patterns that indicated early wear in a truck’s aftertreatment system. The driver noticed no symptoms, and no DTCs were present, but the platform flagged a service window. They brought the vehicle in proactively. Technicians confirmed the degrading part and repaired it before any roadside event or operational delay. The fleet avoided an unscheduled breakdown, costly recovery, and service penalties—all thanks to remote, predictive diagnostics.

This isn’t just theoretical; it’s well-documented in Uptake’s and Daimler Truck North America’s own 2024 materials. These systems use streaming sensor and work order data, machine learning, and cloud analytics to predict problems well ahead of traditional diagnostics, sometimes weeks in advance, recommending specific actions before maintenance becomes reactive.

Similarly, fleets from Freightliner operators using Detroit Connect’s Virtual Technician have been sharing stories like this one on a weekly basis.

Reliably, the engineers from ElectRay have demonstrated that the world’s successes prove vehicle diagnostics systems have expanded well beyond the bolt-on ECU era. The scope of everything from wiring harnesses to cloud orchestration needs a fresh look and redesign centered around zonal intelligence.

Background: Distributed E/E Architecture in Traditional Vehicles and Vehicle Diagnostics Technologies

Automotive manufacturers have faced numerous challenges integrating standalone feature creep ECUs for the last 30 years. Adaptive brakes? One module. Turnable headlights? Another module. By 2024, a luxury sedan would house more than 100 ECUs, 5 kilometers of copper wiring, and 50 kilograms of dead weight. Each ECU module kept vigil over its memory, power, and CAN/LIN interface.

Diagnostic failure tests would need to be performed in a stepwise fashion per module by using the OBD-II and UDS Diagnostic Protocols. This was a period characterized by low subsystem intercommunication and a software footprint limited to a few kilobytes. Fighter jets and vehicles now have around 100 million lines of code. The subsystem complexity has exploded. They can now transmit 25GB of data per hour. A hiccup from a single sensor can trigger dozens of ECUs and flood countless DTCs that drown the real issue. The CAN buses have limited bandwidth and the unsecured seed-key logins are no longer sufficient.

The Shift to SDVs & Zonal Architectures

Software-defined vehicles (SDVs) reverse the traditional approach where the software serves as the soul. SDVs distort the need to integrate legacy cars around wiring.

As per Markets and Markets Research, the SDV market is projected to grow from $213.5 billion in 2024 to $1,237.6 billion by 2030, with a CAGR of 34.0%. This would lead to it driving industry software competitiveness parallel to recovering from Tesla’s enforced competition through software updates.

The need for escape velocity can be achieved through zonal architectures. Rather than merging electronics by function, 4 to 6 zonal controllers per geographic region, such as front-left, rear-right, and center-stack, are used. They replace traditional harnesses with short, high-speed ethernet links, improving wiring by 30-120lbs of curb weight, reducing copper, and saving labor time. Each zone employs low trust, high-fidelity data filtration. The data gets sent to 1-2 HPCs located near the center of gravity where filtered data trust is high.

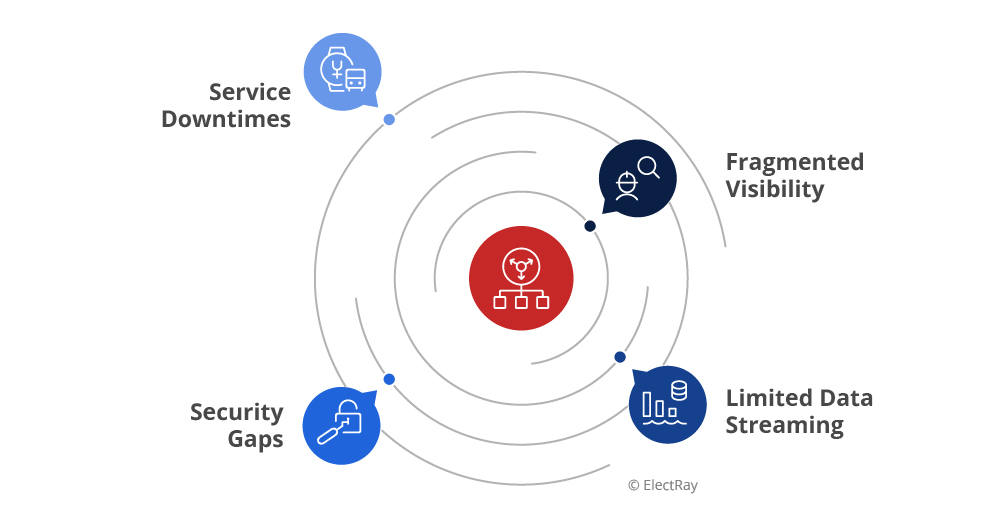

Limitations of Traditional Diagnostics Methodologies Used in Distributed E/E Architecture

- Fragmented Visibility: Cross-system interactions are hidden from technicians because UDS polls ECUs one by one, causing fragmented visibility.

- Limited Data Streaming: AI and Analytics require data streaming capability beyond what 1 Mbps CAN offers.

- Security Gaps: UNECE R155 expectations are violated through plaintext sessions and primitive seed-key handshakes.

- Service Downtimes: The process of sequentially flashing over seventy ECUs can lock a vehicle for six hours, which is detrimental for fleet profit margins.

These challenges highlight the importance of why systems like Detroit Connect predictive platforms automate the identification of critical faults within minutes and slash the time taken to diagnose problems by 70%.

Zonal Intelligence: Redefining the Diagnostic Landscape

The transition from bulky, standalone ECUs to Zonal Intelligence represents a major leap for automotive diagnostics. Unlike skipping preventative maintenance, letting small issues go unchecked, modern architectures are capable of anticipating faults, often isolating issues beforehand without requiring a technician to plug in a scanner.

ElectRay describes Zonal Intelligence as a multi-layer structure of Spatial Intelligence:

Service-Oriented Vehicle Diagnostics (SOVD)

As vehicles become fully software-driven, relying on fixed diagnostic routines linked to specific ECU addresses is becoming outdated. SOVD (Service-Oriented Vehicle Diagnostics) provides a new approach: diagnostics as flexible, service-based APIs. These are delivered through modern protocols like REST/HTTP or Diagnostics over IP (DoIP) and use structured formats such as JSON.

SOVD, standardized by ASAM and AUTOSAR, shifts diagnostics from ECU-centric commands to a service model. This model allows diagnostic “entities” to cover traditional ECUs, zonal controllers, central HPCs, and even cloud containers connected to the vehicle. This means that an OEM can perform diagnostics on a sensor, a sub-system, or an entire vehicle domain—regardless of the hardware module that owns it. This approach streamlines support for rapidly changing architectures.

This service-based design ensures diagnostics keep pace as cars become smartphones on wheels. It supports live cloud connectivity, over-the-air (OTA) updates, and data flows needed for predictive analytics or regulatory reporting.

Why does SOVD matter for OEMs and fleets?

It serves as a key enabler for centralized and modular architectures. Instead of being limited by old protocols, SOVD supports quick OTA programs, speeds up bug fixes, encourages data-driven service models, and makes compliance easier in an increasingly connected and regulated environment.

Key Features & Benefits

- Service-Based Diagnostic Access: Diagnostics are no longer tied to fixed ECUs or addresses. Access is granted by logical service, allowing for flexible toolchains and quick onboarding of new technologies.

- Cloud and OTA Integration Ready: SOVD supports secure remote access, which lets diagnostics, updates, and even repairs happen via the cloud, making OTA campaigns and real-time monitoring simple.

- Centralized and Cross-Domain Compatibility: It works smoothly across zonal controllers, central HPCs, and legacy systems, supporting both distributed and centralized vehicle architectures. This makes it easy to manage mixed or transitioning fleets.

- Dynamic and Scalable Diagnostic Architecture: As vehicle software evolves and architectures change, SOVD enables diagnostic routines and data models to adjust on the fly without being locked into specific tools or hardware.

- Interoperability and Standardization: Built on global standards (ASAM/AUTOSAR), SOVD ensures compatibility between different OEMs, suppliers, and third-party service providers. This future-proofs investments and simplifies compliance.

Centralized and Zonal Diagnostics (Zonal Intelligence)

In the age of Software-Defined Vehicles (SDVs), the situation has changed significantly. Vehicle diagnostics is no longer a messy puzzle of disconnected ECUs. Instead, the industry is adopting Zonal and Centralized Electrical/Electronic (E/E) architectures that combine data from all parts of the vehicle into one smart platform

In this modern method, diagnostics are gathered within a central high-performance computer (HPC). This HPC does more than collect fault codes; it actively monitors, examines, and connects health data from all major areas, including powertrain, infotainment, safety, and ADAS. Instead of letting each ECU operate independently, the new system brings all diagnostic events together. This allows for quick identification of patterns and cross-system issues.

This model relies on high-speed automotive Ethernet and modern protocols like Service-Oriented Vehicle Diagnostics (SOVD), rather than slow, isolated diagnostics. These systems enable real-time analysis, remote troubleshooting, and fast over-the-air (OTA) software updates, all managed centrally. As complexity increases, such as with advanced driver assistance or electric mobility, this unified intelligence helps keep vehicles efficient, safe, and continuously updatable.

Key Features & Benefits

- Localized Fault Detection & Preprocessing: Zonal gateways identify issues at the source by preprocessing signals before sending them to the central HPC. This means real problems are found quicker, and false alarms are filtered out.

- Scalable and Modular Architecture: The architecture is designed to easily add new functions and features. Introducing another zone or vehicle domain does not disrupt the system; it improves it.

- Supports SOVD & OTA Readiness: Diagnostics are made for smooth integration with SOVD APIs and over-the-air updates, making remote troubleshooting, patching, and feature deployment standard practice.

- Designed for SDV Complexity: The zonal intelligence model manages the large flow of data from modern software-driven cars, handling everything from high-resolution sensor fusion to adaptive energy management.

- Enhanced Cybersecurity Integration: Centralization ensures a consistent security policy for diagnostics. This allows for strong threat monitoring, encrypted data flows, and compliance with strict regulations like UNECE R155.

By shifting from fragmented fault detection to holistic, centralized diagnostics, OEMs and mobility providers gain a smarter, quicker, and more resilient platform for the SDV era. This platform is ready to evolve as vehicles and customer expectations change

Cloud Assisted & OTA Diagnostics

Diagnostics are no longer confined to closed-box exercises exclusive to dealerships or service stations. Cloud connectivity transforms diagnostics to the present and helps by providing continuous monitoring, real-time collaboration between OEM and dealer, and streamlined compliance across different regulatory regimes globally.

Cloud-assisted and over-the-air (OTA) diagnostics have become essential tools for providing ongoing, remote, and predictive health insights throughout the vehicle’s lifecycle.

Key Features & Benefits

- Real time remote fault monitoring: These days, cars transmit comprehensive sensor and diagnostic data straight to safe cloud dashboards via encrypted channels. Manufacturers and service teams can now quickly identify anomalies, new faults, or unusual usage patterns before they worsen by monitoring vehicle health as it occurs—from any location. Support is now more proactive, effective, and transparent for OEMs and customers as problems that previously went unnoticed between service visits are now flagged instantly.

- Predictive maintenance and fleet intelligence: Diagnostic platforms use cutting-edge AI and machine learning to examine patterns across thousands of cars and find early indicators of system instability or component wear. Beyond simply preventing malfunctions, these insights help operators plan maintenance, anticipate repairs, and optimize parts logistics, which lowers operating costs and downtime. OEMs can continuously enhance product quality for each owner and fleet manager and obtain a comprehensive understanding of reliability trends.

- Over the AIr (OTA) software and configuration updates: Gone are the times when one had to go to the dealership for every software patch related to recalls. Today, diagnostic ecosystems facilitate the smooth OTA delivery of configuration modifications and software updates, whether they are needed to address bugs, add new functionality, or meet legal requirements. Vehicles can be updated globally, rolled back if needed, and spaced out for safety, keeping them safe, up to date, and more capable as technology advances.

- Customer centric service model: Diagnostics is about improving the customer experience, not just about fixing cars. Automakers can set up appointments at the best times, send personalized service notifications, and offer remote or mobile support thanks to real-time data. Consumers gain from new value-added services that meet contemporary digital expectations, increased transparency, and less disruption. This customer-first strategy enhances brand reputation, fosters customer loyalty, and makes every service encounter enjoyable.

OEMs and fleet operators access real-time status and trending analytics through dashboards. OTA diagnostics and firmware updates reduce unplanned downtime and accelerate recall processes.

Regulatory and warranty information can be exchanged dynamically, improving the speed of resolving issues across the industry.

AI/ML Driven Diagnostics & Prognostics

This marks the innovation shift from reactive to proactive maintenance. By integrating machine learning with an avalanche of vehicle data, these systems monitor for signs of trouble far earlier than the triggering of a sensor or the illumination of a check engine light.

Key Features & Benefits

- Early Anomaly Detection Beyond DTCs: Waiting for traditional fault codes is just one aspect of modern AI-powered diagnostics. Long before a DTC ever manifests, these systems identify anomalous behaviors such as random current flow, micro-vibration shifts, or actuator lag by continuously evaluating high-resolution sensor data and subtle system trends in real time. This helps uncover the “unknown unknowns” that lie beneath the surface by enabling proactive investigation and targeted repairs days or even weeks ahead of what would be possible with traditional diagnostics.

- Predictive maintenance and reduced downtime: Predictive models predict when components will begin to deteriorate based on actual usage patterns and operating conditions, as opposed to reactive repairs. Equipped with precise “time-to-failure” estimates, service departments are able to pre-order the exact parts they need and schedule interventions during scheduled downtime. This reduces the number of emergency roadside incidents and transforms unscheduled repairs into low-impact, economical service windows.

- Adaptive & continually improving models: AI engines are continuously retrained using new fleet data, so they are never static. The models adapt to real-world conditions, hardware variations, and software updates by learning new failure signatures, incorporating technician feedback, and fine-tuning thresholds for critical alerts. This guarantees that diagnostic precision only gets better with time, automatically adjusting to the particular environment of each fleet.

- Fleet wide insight & warranty optimization: By bringing diagnostics from all over the fleet together, advanced analytics can reveal patterns that might otherwise go undetected, such as frequent part failures or usage-driven wear. In order to support more intelligent warranty strategies and early recalls, OEMs and operators can monitor reliability by component, region, or vehicle age. The ultimate outcome is a sharp decline in needless claims or repeat repairs, fewer “no trouble found” returns, and prompt identification of systemic problems.

Cybersecurity Aware Diagnostics

As vehicles evolve into fully connected, software-defined platforms, diagnostics must not only monitor vehicle health but also ensure secure access and trust. Cybersecurity aware diagnostics integrates security mechanisms into every diagnostic interaction, protecting critical vehicle systems from malicious access, spoofing, or manipulation.

Cybersecurity aware diagnostics integrate security measures into the diagnostic processes of SDVs to protect zonal architectures from cyber threats. Leveraging secure protocols (e.g.TLS, HSMs) and intrusion detection systems (IDS), these diagnostics monitor Ethernet based networks and zonal controllers for unauthorized access or anomalies. By ensuring compliance with standards like ISO/SAE 21434, they safeguard diagnostic data and OTA updates, maintaining vehicle integrity and user trust in connected systems.

Key Features & Benefits

- Secure access to diagnostic interfaces: Advanced techniques like digital certificates, hardware security modules (HSMs), and role-based privileges are used to authenticate all diagnostic requests, whether they are local, remote, or cloud-based. Significantly lowering the possibility of spoofing or illegal tampering, only authorized individuals, instruments, and applications can access private procedures or change vital vehicle data.

- Encrypted communication channels: Modern protocols like TLS 1.3 ensure end-to-end security for diagnostics traffic, whether it is internal (across zonal Ethernet) or external (to cloud services). This keeps data private and authentic from source to cloud by protecting fault codes, logs, and even over-the-air updates from manipulation and eavesdropping.

- Enhanced trust for OTA & cloud based diagnostics: Before being executed, every software update, remote procedure, and data exchange is subjected to stringent integrity checks, including runtime security monitoring, hash verifications, and digital signatures. Vehicles only run validated, trusted code and data, guarding against malware and update spoofing, because any indication of compromise automatically initiates safe fallback.

- Compliance with global cybersecurity regulations: Every diagnostic procedure is designed to satisfy stringent requirements such as ISO/SAE 21434 and UNECE R155/R156. In addition to providing regulators with ready-to-audit evidence, automated policy enforcement, secure event logging, and integrated intrusion detection protect system integrity and user privacy at scale.

Comparison: Traditional vs SDV Diagnostics

| Attribute | Distributed ECU Model | Zonal + SOVD Model |

|---|---|---|

| Fault Isolation | ECU-level DTCs; cascades mask cause | Zone-level correlation plus AI-driven root cause analysis |

| Data Channel | CAN/LIN < 1 Mbps | CAN/LIN < 1 Mbps |

| Software Update Time | 4–6 hour serial flashing | < 1 hour parallel OTA shards |

| Harness Impact | Neutral (baseline, limited optimization) | 30–50% lighter, simpler loom; reduced wiring/copper |

| Cybersecurity | Seed-key, no TLS; limited access control | Mutual TLS 1.3, certificate rotation, role-based access |

| Predictive Maintenance | Rare, reactive; diagnostics after failure | Fleet-wide AI forecasts (e.g., Volvo Blue, Daimler/Uptake) |

| Remote Service | Physically at shop: OBD-II connector or tool-per-ECU | Cloud & mobile portals; remote, centralized service/updates |

| Diagnostic Access Mechanism | Via OBD port or direct access to each ECU | Via front or central HPC/gateway (also supports DoIP/SOVD endpoints) |

| Service invocation | UDS over CAN/LIN (local serial session) | SOVD (Service-Oriented Vehicle Diagnostics) using DoIP (Diagnostics over IP) |

| Tool Dependency | OEM-specific legacy tools; offline, on-site techs | Cloud-native/remote APIs, web/mobile tools, multi-OEM support |

| Data Logging | Basic DTCs and freeze-frame logs; limited time/cause context | Basic DTCs and freeze-frame logs; limited time/cause context |

Strategic Importance of Diagnostics in SDV

Diagnostics has morphed from a compliance chore to a boardroom lever:

- Predict-before-fail Uptime: Volvo’s predictive diagnostics detected issues like wheel bearing degradation and NOx sensor faults early, much before any DTC appeared. This enabled proactive repairs thereby preventing breakdowns and downtime.

- Feature Unlocks: Health-verified subsystems let OEMs unobtrusively sell torque boosts or ADAS upgrades without showroom visits.

- Regulatory Agility: Continuous cybersecurity monitoring and real-time evidence collection streamline UNECE R155 compliance audits, enabling OEMs to address regulatory findings and recalls more quickly

In January 2025, Uptake’s predictive diagnostics flagged a turbo actuator issue on a Daimler Freightliner Cascadia before any DTC appeared. Remote cloud analytics alerted the fleet, which fixed the part proactively and helped in avoiding an expensive breakdown. This kind of remote, AI-powered predictive diagnostics is now live across hundreds of Daimler trucks.

Buoyed with such advances in diagnostic abilities, a global market research published by “The Business Research Company” estimates the market for predictive diagnostics at 27 billion and rising, as Uptake implements 65 data-science models across Daimler fleets to reduce unplanned maintenance events.

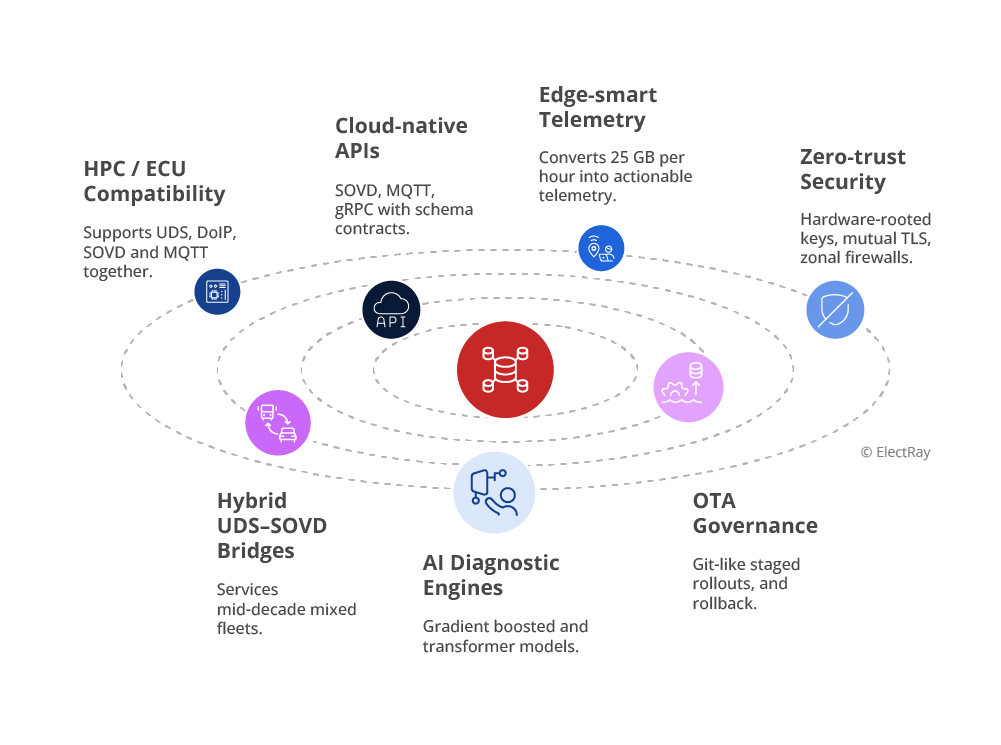

What OEMs Need in Their Diagnostic Stack Going Forward

- HPC / ECU Compatibility – Supports UDS, DoIP, SOVD and MQTT together ensuring seamless diagnostics across legacy ECUs and modern HPCs.

- Cloud-native APIs: SOVD, MQTT, gRPC with schema contracts.

- Edge-smart Telemetry: Converts 25 GB per hour into actionable telemetry bursts while preserving telemetry anomalies.

- Zero-trust Security: Hardware-rooted keys, mutual TLS, zonal firewalls, and policy firewalls.

- Hybrid UDS–SOVD Bridges: For servicing mid-decade mixed fleets.

- AI Diagnostic Engines: Gradient boosted and transformer models trained on fleet history.

- OTA Governance: Git-like versioning, staged rollouts, and instant rollback.

Challenges and Future Directions

Turbulence during transition is definitely approaching fast. Hybrid ECU and zonal line-ups will be common in showrooms into the late decade, requiring dual-stack tools. Over the past five years, standard bodies like ASAM have released SOVD 1.0, but there are not enough interoperability labs. Retraining technicians is now essential. Sniffing the network and API debugging are now as important as using torque wrenches. Privacy laws in regions like Europe and India are getting stricter, so automakers now need to use techniques like edge anonymization and federated learning to protect driver data while still enabling fleet-wide analytics.

How ElectRay Enables This Vehicle Diagnostic Evolution

ElectRay speeds up the modernization of diagnostics with a solid, production-ready toolkit:

- Production Grade AUTOSAR Software Stacks: ElectRay’s foundation includes strong SOVD-to-UDS translators, designed SOVD gateways, and full support for both classic and new protocols. These include UDS, OBD, OBDonUDS, ZEVonUDS, and intelligent flash bootloaders. This setup ensures every vehicle, from traditional ICE models to the latest zero-emission designs, communicates in a diagnostic “language” that meets standards and is ready for the future.

- Remote Access Modules: Diagnostics no longer stay in the shop. ElectRay provides smooth access through MQTT and Diagnostics over IP (DoIP). This allows remote technicians, cloud apps, and mobile tools to interact with vehicles securely and instantly, regardless of their location.

- OTA Update Capabilities: The over-the-air and firmware-over-the-air (OTA/FOTA) modules ensure vehicles get important software updates, recall fixes, and new features whenever necessary. Updates are managed with precise control to reduce downtime and avoid risky manual interventions.

- Cloud Integration: ElectRay’s platform connects real-time data to powerful cloud-monitoring dashboards. This enables remote diagnostics, predictive analytics, and health checks across the fleet. Issues are identified early, giving support teams the insight and often the solution before problems occur on the road.

- Requirements & Data Authoring: Flexible data-modeling tools support ODX, OTX, ARXML, CDD, JSON, and REST. This makes authoring, testing, and sharing diagnostic requirements quick, efficient, and highly compatible across tools and OEM processes.

ElectRay’s role in vehicle diagnostics is not about showcasing impressive numbers or making unrealistic promises. It goes beyond and focuses on helping OEMs modernize their fleets.

Our offerings include a flexible system that connects older and newer vehicles, supports easy remote service and software updates, and simplifies the process of writing requirements. The outcome is faster diagnostics, smoother compliance, and fewer surprises for drivers and fleet managers.

With strong tools for every diagnostic level, from SOVD gateways to cloud dashboards, ElectRay keeps vehicles running smarter, not just harder.

Conclusion: The Road Ahead

Zonal intelligence is changing diagnostics for OEMs in both passenger cars and commercial vehicles. Automakers no longer rely on isolated control units and random troubleshooting.

Today’s SDV platforms provide a complete view that allows them to spot, locate, and fix faults across the whole vehicle in real time. This change means that an unexpected warning in a passenger EV can trigger immediate analysis across different zones. In heavy-duty trucks, the system can often self-diagnose and schedule software updates before the driver even realizes something is wrong.

For OEMs, this change is not just technical; it is strategic. Zonal diagnostics enable smooth over-the-air updates, better compliance with cybersecurity and safety rules, and new methods to ensure vehicle uptime and offer feature upgrades. Drivers and fleet managers benefit from fewer service disruptions, clearer experiences, and vehicles that can improve and adapt over time.

Achieving this future requires close cooperation among OEMs, suppliers, and technology providers. By adopting open platforms, shared data standards, and strong security measures, the industry can turn complexity into an advantage.

Looking ahead, the vehicles rolling off production lines will be smarter, safer, and more responsive to drivers and their surroundings because diagnostics will serve as a source of resilience and opportunity rather than risk and friction.

Ready to turn complexity into your competitive advantage. Partner with ElectRay and let’s set a new standard for intelligent diagnostics together.